Fueling the growth of modern food processing are not just high‑tech ingredients or smart packaging, but the mechanical heart of production lines—gear motors. These compact units translate electric power into precise mechanical motion, enabling everything from conveyor belts and mixers to labeling robots. In this article, we dive into the fundamentals of gear motors, examine how different types perform on food‑processing equipment, and draw a clear comparison that helps plant managers choose the right motor for their needs.

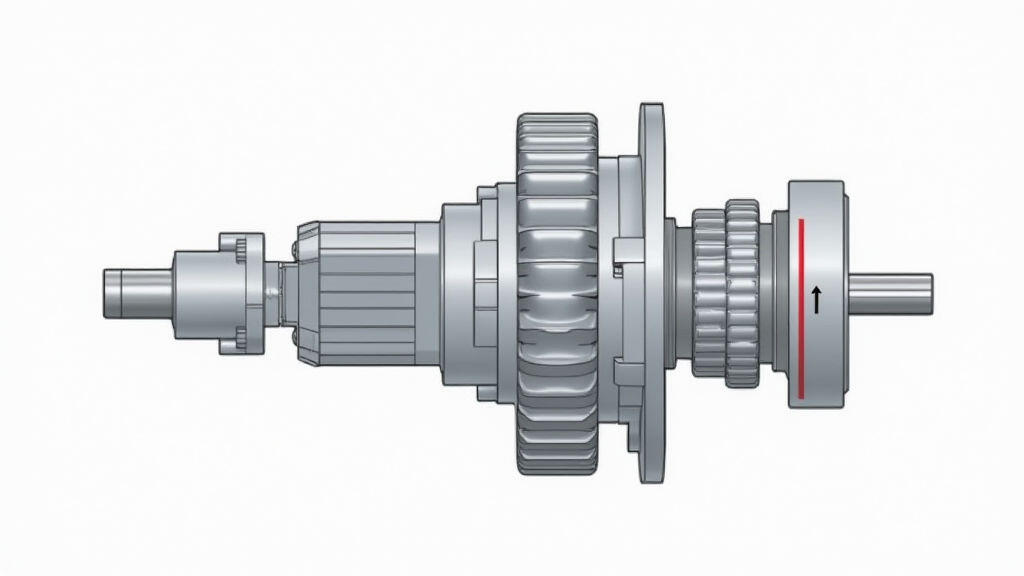

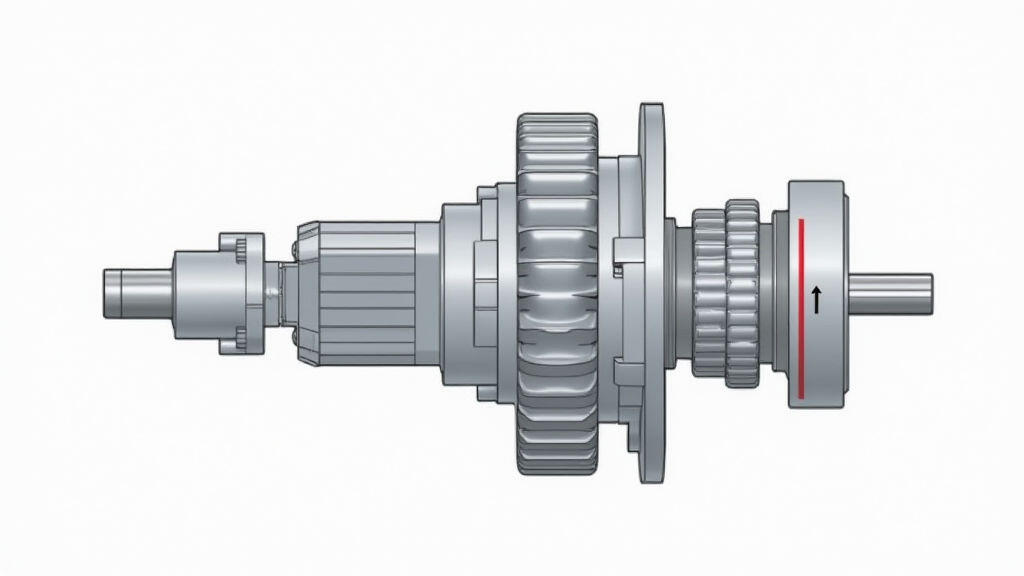

A gear motor is essentially a motor combined with a gear reduction system. The electric motor driver drives a shaft, and attached gears reduce that shaft speed while increasing torque. The basic equation that governs the gear reduction is:

nout = nin ÷ i — where n is speed and i is the gear ratio.

This reduction is crucial in food processing: many processes require low speed but high torque. For example, a dough mixer demands steady, low‑speed rotation but must lift large load masses. Gear motors deliver that combination while keeping the overall unit compact.

There are mainly two types of gear sets used:

When evaluating a gear motor for a food plant, not only should you consider torque and speed, but also the following:

| Motor Type | Torque (Nm) | Speed (rpm) | Duty Cycle | Typical Food Application |

|---|---|---|---|---|

| Planetary Gear Motor 12 V DC | 0.5–5.0 | 300–2,000 | Continuous | Conveyor damping rollers, small mixers |

| Spur Gear Motor 24 V DC | 5.0–20.0 | 200–800 | Intermittent | Dough mixers, grain hoppers |

| Helical Gear Motor 48 V AC | 20.0–50.0 | 100–500 | Continuous | Heavy‑weight slicers, automated filling machines |

| IP68 Food‑grade Gear Motor 24 V DC | 5.0–15.0 | 200–1,200 | Continuous | Cleaning‑in‑place (CIP) applications |

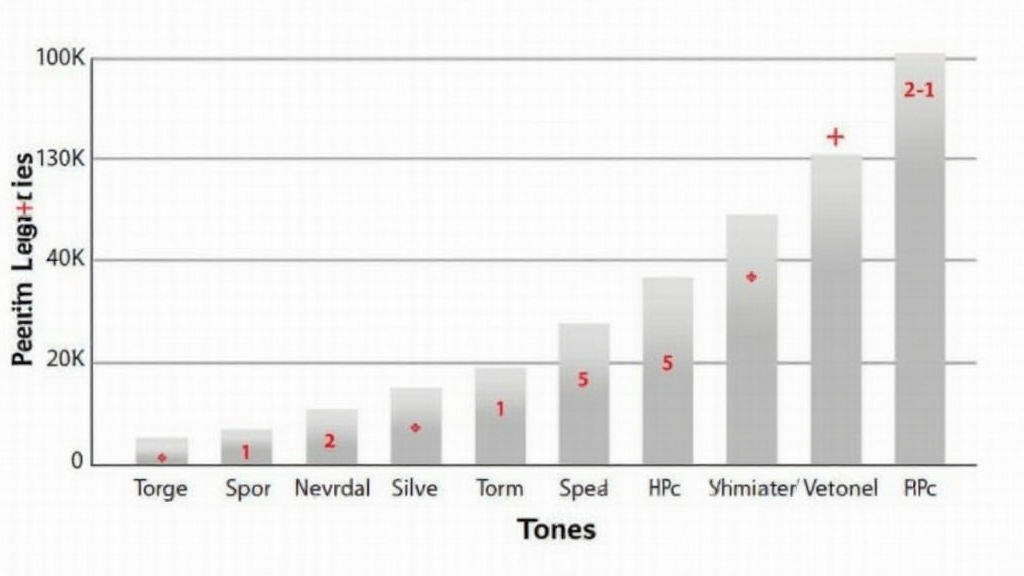

As you can see, planetary gear motors excel in speed‑critical tasks due to their compact ratio, whereas helical gear motors bring the raw torque needed for heavy‑duty machines. Selecting the right gear type hinges on the specific process demands and the environment in which the motor will operate.

A mid‑size bakery recently retrofitted its production line. The existing conveyor used a standard 24 V DC spur gear motor that struggled with uneven torque distribution, causing jams during high‑bake batches. After switching to a 12 V planetary gear motor with a 40:1 reduction ratio, the conveyor achieved consistent torque, reducing jam incidents by 30 %.

The bakery also upgraded its dough mixer from a 24 V spur motor to a 48 V helical gear motor. The increased inlet voltage allowed the mixer to operate at a lower gear ratio without overheating, thus extending the motor’s life by roughly 20 % while improving mixing uniformity.

These upgrades demonstrate how performance comparison, matched to specific food‑processing tasks, delivers tangible benefits in productivity and equipment reliability.

With Industry 4.0, gear motors are moving from simple drivers to intelligent actuators. Embedded sensors now monitor vibration, temperature, and motor health in real time. Predictive maintenance algorithms can forecast trouble before a motor fails, drastically cutting downtime.

Additionally, soft‑starter technology and variable frequency drives (VFDs) enable finer motor control, ideal for processes that require variable speeds, like adjustable conveyor belts for product chutes. Food safety regulations are also pushing for motors with improved hygiene—supporting antimicrobial coatings or stainless‑steel housings that can be sanitized without compromising performance.

Gear motors may be small components, but their impact on food processing is enormous. Understanding their principles—gear ratio, torque, speed—and how they perform in real‑world settings allows plant managers to align motor choice with process requirements. The comparative insights provided herein help evaluate planetary versus helical gear motors, balance speed and torque needs, and identify the future of smart, hygienic gear motors that will keep production lines running smoothly while meeting stringent food‑safety standards.

Ultimately, selecting the right gear motor is not just about meeting mechanical specifications; it’s about ensuring consistent product quality, reducing downtime, and preparing your facility for the next wave of technology. By investing in the best motor solutions today, food manufacturers can enhance operational efficiency, expand capacity, and stay ahead in a highly competitive market.

Leave A Reply

Your email address will not be published. Required fiels are marked